The world’s unique spunbond nonwoven available in three different materials

In addition to common features such as a high level of filament evenness (in punch density and fiber opening), air permeability, no napping, and edge fray resistance, the availability of nylon, polyester, and polypropylene provides an added dimension of variety to the Eltas brand, with different characteristics that meet practically any need in a broad array of applications in every field of industry.

Material characteristics

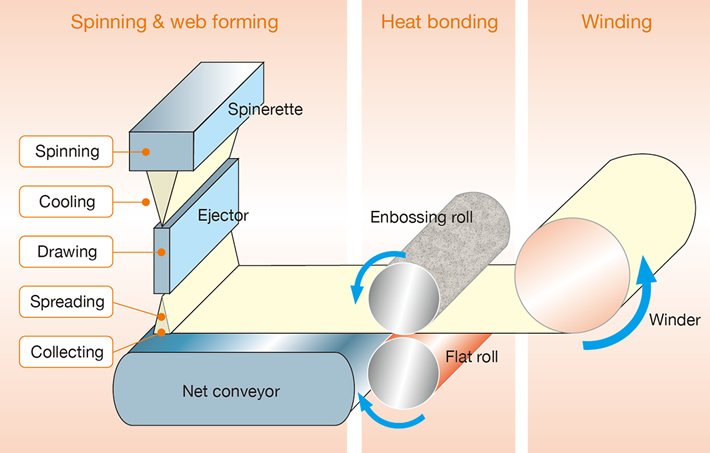

Production Process

Eltas is produced using the spunbond process.

Synthetic resins (polymers) are heated and melted, extruded through fine holes in the spinnerets, and drawn into continuous filaments. Next, webs of evenly distributed filaments are bonded by thermocompression with the embossing roll to form a bonded sheet.

Emboss types

A soft, high-volume pattern ofhorizontal bars

A soft pattern ofsmall dots

A strong, high-tension flat weave pattern