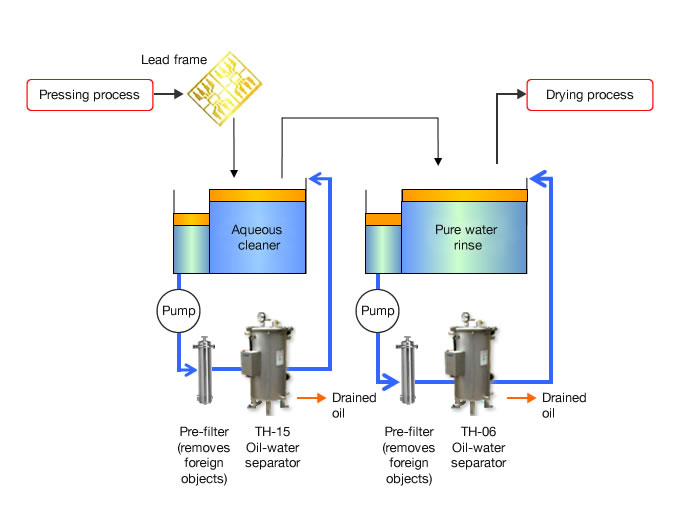

EUTEC™ FS - Installation case study 1

(1) Degreasing & cleaning of semiconductor lead frames (pressing process)

| Aim of EUTEC installation | Removal of press oil contaminant from cleaning fluid |

|---|---|

| Expected benefits of EUTEC installation | Prolong service life of cleaning fluid and prevent re-attachment of oil to cleaning target |

| Cleaning target | Strip-shaped semiconductor lead frames |

| Type of dirt/contaminant | Press oil |

| Type of cleaner being used | Aqueous cleaner |

| Operating temperature of cleaner | 50℃ |

| Model of oil-water separator used (process flow rate) | TH-15 (15L/min), TH-06 (6L/min) |

Installation flow diagram

*Click here for more examples of cleaning-related installation flows.