Power plant-related applications

Details of power plant-related applications of EUTEC™ FS filter

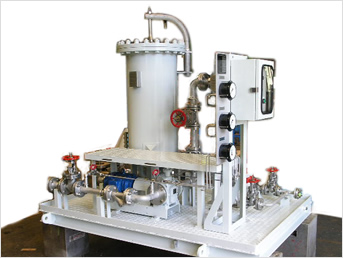

[EUTEC™ coalescer-type turbine oil purifier]

EUTEC coalescer-type turbine oil purifiers are oil-water separation devices that make full use of Our own extensive nonwoven fiber technology, and are designed to remove moisture and microscopic particles from the lubricating oils used in turbines. EUTEC oil purifiers achieve higher performance and faster flow rates than conventional methods with greater compactness and lower running costs.

EUTEC coalescer-type turbine oil purifiers are oil-water separation devices that make full use of Our own extensive nonwoven fiber technology, and are designed to remove moisture and microscopic particles from the lubricating oils used in turbines. EUTEC oil purifiers achieve higher performance and faster flow rates than conventional methods with greater compactness and lower running costs.

[Features of EUTEC™ coalescer-type turbine oil purifiers]

Feature 1

- Captures and separates out dirt, water and other contaminants found in turbine lubricating oil

- Because EUTEC filters use microfilament material for the filter media, they achieve high-performance in capturing dirt and other contaminants in turbine oil. They also simultaneously capture free water/moisture mixed in with the turbine oil, concentrate and coalesce it, and separate it from the oil.

Feature 2

- Long service life

- Unlike absorption-type water separation filters, because EUTEC filters work by passing both the oil and water through the filter medium, no water remains in the filter after separation. Accordingly, there is no longer a need to consider the reduction in service life of filter elements due to water/moisture saturation.

In addition, because EUTEC filters use microfilament material that is highly porous (high-void composition) despite its fine pore size, they also achieve a significant increase in the volume of dirt that they can retain.

Feature 3

- Virtually no impact on water separation performance even when the filter is clogged with dirt

- Our own, independently developed filter design means that the increase in differential pressure caused by clogging of the filter material with dirt and other contaminants has virtually no effect on the filter's water separation capabilities (according to Our own in-house assessments, under conditions of coalescer-exchange differential pressure of 100kPa or below.)

Feature 4

- Filtration devices can be designed to conform to JIS/ASME and various other standards

- Purifier devices can be manufactured to conform not only to the standard JIS specifications used by us, but also to customers' requested specifications.

For further details, please consult our sales department.

[Equipment specifications]

| Applicable oils | Additive turbine oil ISO VG#32 |

|---|---|

| Oil temperature | 60℃ |

| Water separation capacity | Reduces water/moisture concentration in total oil volume 10,000→500ppm after 5 cycles (*1) |

| Degree of purification | Improves purity grade from NAS Class 12→7 after 5 cycles (*1) |

| Process flow rate/throughput | 300-20,000L/h |

*According to internal assessments.

(*1) Total oil volume is defined as five times the volume of oil circulated per hour.

Example: where volume of oil circulated per hour is 4,000L/h the total oil volume is 20,000L (=4,000 x 5).