EUTEC™ FS/MF - Installation case study 19

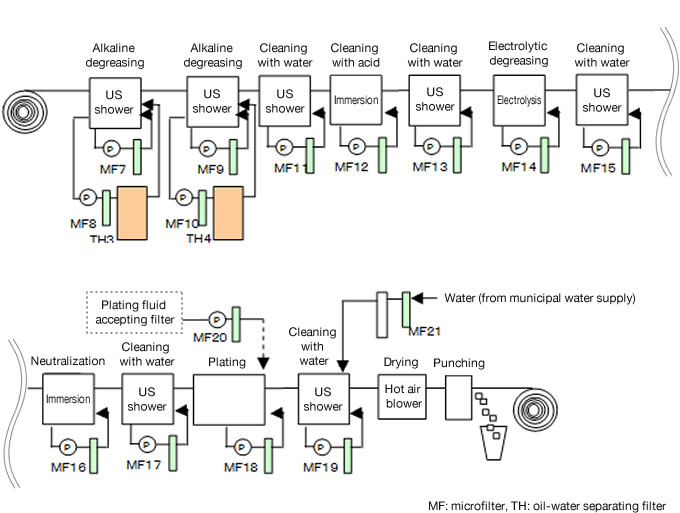

(19) Application in connector manufacturing 2 (plating process)

| Aim of EUTEC installation | Separation of oil during the degreasing process before plating of connector parts |

|---|---|

| Expected benefits of EUTEC installation | Improve quality of plating process and prolong service life of plating fluid |

| Cleaning target | Coiled metal sheet |

| Type of dirt/contaminant | Press oil, dust |

| Type of cleaner being used | Alkaline degreaser |

| Operating temperature of cleaner | 60℃ |

| Model of oil-water separator used (process flow rate) | TH-15 (15L/min) |

Plating process

| Process | Filter usage point | Filter | Purpose of filter installation | Asahi Kasei filter series used |

|---|---|---|---|---|

| Plating | Alkaline degreasing | MF7, MF 9 | Removal of foreign objects | KNP, AMWPP |

| Alkaline degreasing | MF8, MF10 | Removal of foreign objects, pre-filtering |

KNP, AMWPP | |

| Alkaline degreasing | TH3, TH4 | Separation of oil | TH oil-water separator | |

| Cleaning with water | MF11 | Removal of foreign objects | KNP, AMWPP | |

| Cleaning with acid | MF12 | Removal of foreign objects | KNP, AMWPP | |

| Cleaning with water | MF13 | Removal of foreign objects | KNP, AMWPP | |

| Electrolytic degreasing | MF14 | Removal of foreign objects | KNP, AMWPP | |

| Cleaning with water | MF15 | Removal of foreign objects | KNP, AMWPP | |

| Neautralization | MF16 | Removal of foreign objects | KNP, AMWPP | |

| Cleaning with water | MF17 | Removal of foreign objects | KNP, KYS | |

| Plating | MF18 | Removal of foreign objects | KNP, KYS | |

| Cleaning with water | MF19 | Removal of foreign objects | KNP, KYS | |

| Plating-fluid accepting filter | MF20 | Removal of foreign objects | KNP, KYS | |

| Generation of rinse water | MF21 | Removal of foreign objects from rinse water | KNP, KYS |

*Click here for more examples of cleaning-related installation flows.